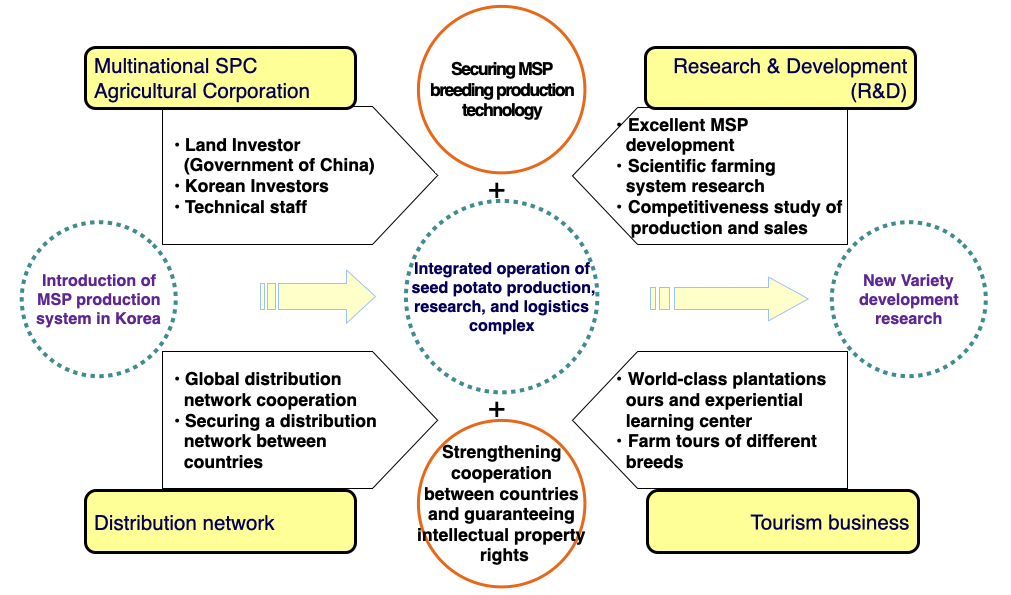

1. Business area and future direction of development

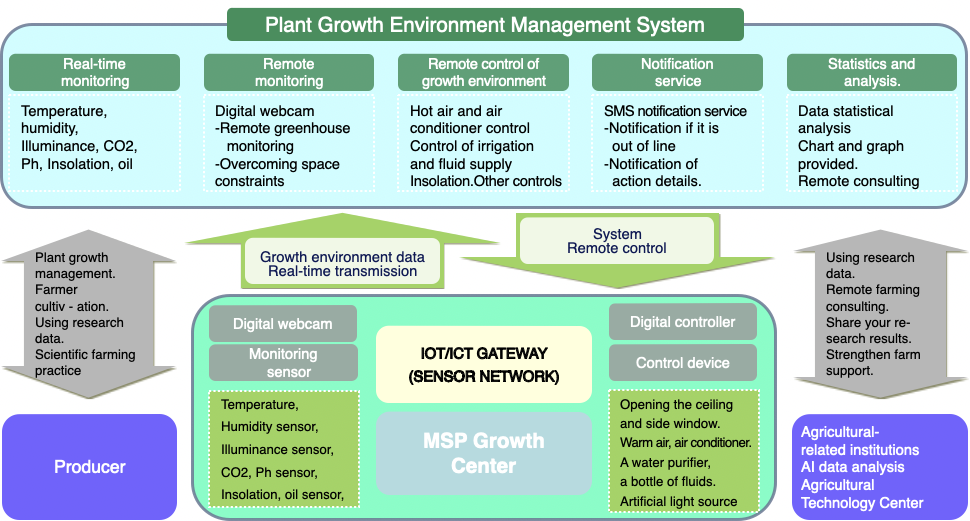

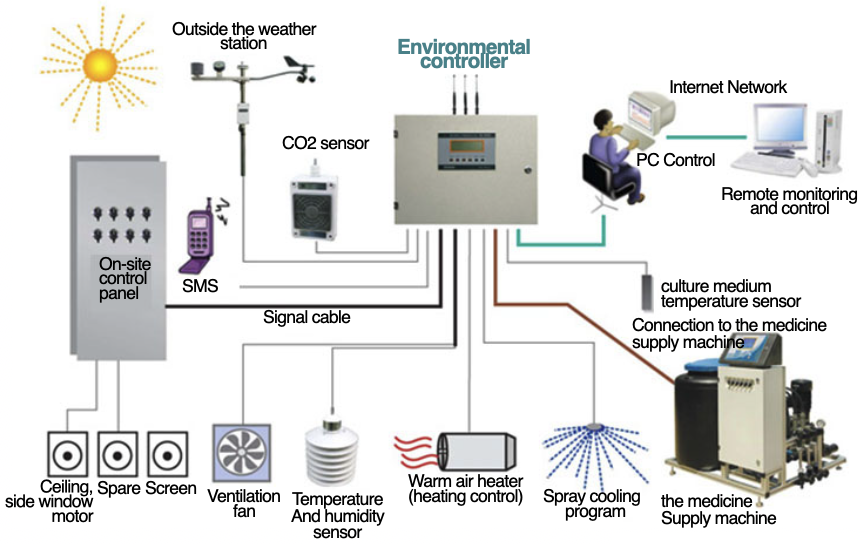

Seed Potato Culture, Proliferation, Introduction of digital *IOT/ICT system in production and Realization of scientific farming through IOT/ICT of all processes

- Geothermal and solar heat utilization system

- Maximize energy self-sufficiency

- Establishment of advanced wired and wireless communication infrastructure

- Remote control, integrated control system

- Lighting in the complex → LED application

- Utilization of plant light sources in the cultivation complex

- Utilization of plant oxygen excretion action

- Carbon dioxide emission rights

- Perform central control room function

- System control, inspection

- 24-hr all-time operation

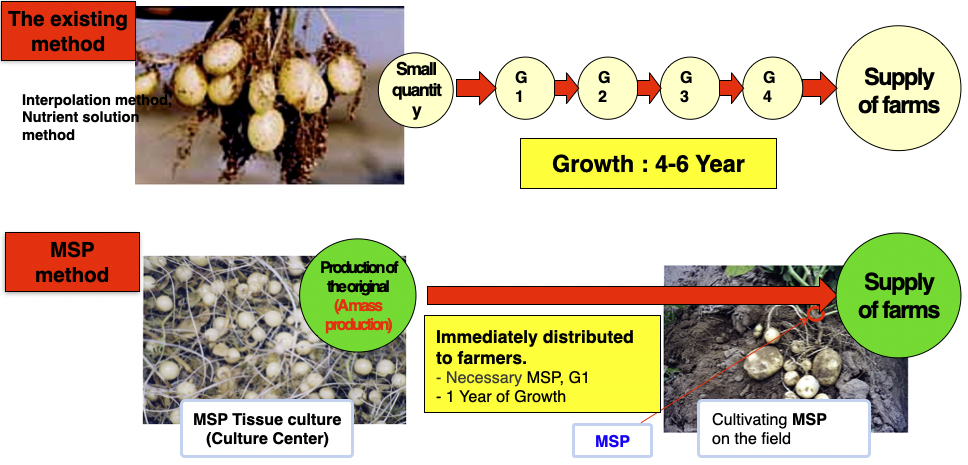

- Culture, proliferation technology development

- Research on breed improvement and nutrient solution (R&D)

- Industry-university cooperation, nurturing human

- Seed potato shipment supply

- Establishment of sales and distribution plan

- Export and trade in overseas markets